Background

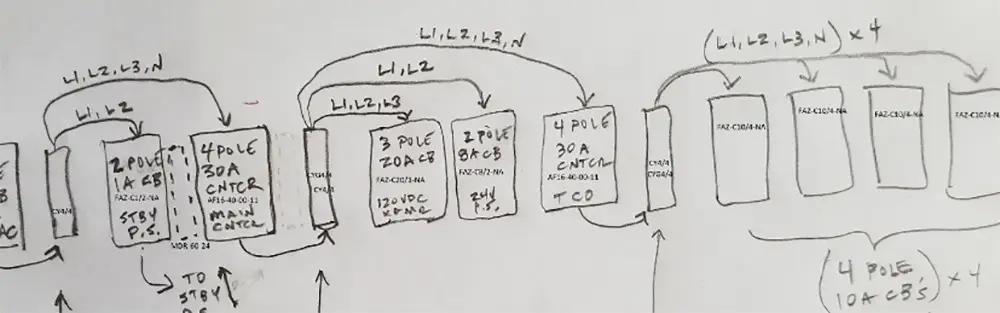

Agility EMS has progressed to the design verification stage of an exciting project for one of our customers. We’ve taken the design of a new DIN rail assembly from napkin sketch to prototype to the design verification stage component that will provide power to heavy-duty industrial machines.

Our customer is an OEM manufacturer that produces sophisticated, large-scale industrial machine equipment. Agility has worked with this manufacturer for a number of years. Recently, the company approached Agility for help designing a DIN rail for one of its new industrial machines.