Sensing the world’s needs.

Honeywell invents and manufactures technologies to address some of the world’s toughest challenges initiated by revolutionary macrotrends in science, technology and society. A Fortune 100 company, they create solutions to improve the quality of life of people around the globe. Honeywell serves thousands of customers in four core industry segments: Industrial, Medical, Transportation and Aerospace / Military.

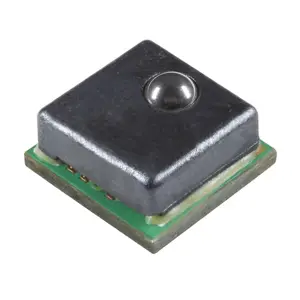

Board Mount Pressure Sensors

Full line of industrial-grade sensors: media-isolating design, multiple ports, electrical configurations, and outputs; ranges from 0 psi to 250 psi.

Honeywell’s sensing element design consists of four piezoresistors on a chemically etched silicon diaphragm. A pressure change will cause a strain in the diaphragm and the buried resistors. The resistor values will change in proportion to the stress applied, which produces an electrical output. You will find our components performing in potential applications including dialysis equipment, blood analysis, centrofusion and oxygen and nitrogen gas distribution, HVAC devices, data storage, process controls, industrial machinery, pumps, and robotics.

Full line of industrial-grade sensors: media-isolating design, multiple ports, electrical configurations, and outputs; ranges from 0 psi to 250 psi.

Heavy Duty Pressure Sensors

Built for the toughest applications. Our heavy duty pressure products are known industry-wide for enhanced quality, reliability, & service.

When reliability is demanded, Honeywell delivers. Heavy Duty Pressure Transducers are found in applications where they cannot be easily replaced — where supreme durability is a top priority. That’s why you’ll find Honeywell heavy duty pressure products performing expertly in many potential applications, such as compressors and hydraulic controls, and in industries as diverse as aerospace, medical, transportation, agriculture, refrigeration, and industrial. Our full line of products deliver enhanced performance and reliability, plus: absolute, gage and sealed-gage measurement; a wide array of pressure ranges, port styles, termination types, and outputs; package types from miniature surface mount sensors to high-end stainless steel isolated (for stringent process control); pressure ranges from 3 psi to 8,000 psi; and corrosion resistance.

Force Sensors

Leadership, in full force. Whether it’s critical applications such as IV drips or dialysis, or serious engineering like robotic end-effectors.

Honeywell offers a broad line of force sensor options. Honeywell force sensors also deliver built-in stability and flexibility, to provide enhanced performance in most applications.

Toggles and Rockers

MICRO SWITCH toggle and rocker switches control machine function to construction and agriculture equipment OEMs, in addition to aerospace, air transport, armored fighting vehicles, office equipment, medical/dental, valves and vending machines.

Our toggle and rocker switches withstand wet, dust, dirty environments and are designed for use in harsh environments. With many configurations available, Honeywell engineers can help with quick customization.

Limit Switches

No limit leadership. Available with a variety of actuators, electrical specifications, terminations, circuitries and sealing ratings, Honeywell limit switches offer superior flexibility and performance.

These precision snap-action switches — sealed in rugged housings — are used to detect presence or absence in areas where physical contact is allowed.

Basic Switches

The switch is on. Honeywell’s snap-action basic switch is simple, superior, durable, and irreplaceable. Globally compliant and known worldwide for their compact and lightweight design, MICRO SWITCH snap-action switches are designed for accurate repeatability and extended life.

MICRO SWITCH Basic switches are designed for presence and absence detection where physical contact with an object is permissible. They also excel in applications requiring simple on-and-off actions.

The Premium families of MICRO SWITCH Large and Subminiature switches were designed for high-precision applications where the cost of a switch failing is high. Originally developed to support United States aircraft in World War II, advancements in packaging and operating controls have helped further expand applications over the past 75 years while maintaining enhanced accuracy and repeatability.